Serving our customers with best-in-class, advanced temporary traffic signal solutions.

A history of design

Traffic Group Signals reputation is built on over 100 years of manufacturing innovation from Pike Signals and Hollco.

Our robust portable traffic signal designs have been refined extensively to meet the high demands of UK’s highways industry, developed over years of testing and collaboration with our industry partners.

We are proud of a number of industry firsts, such as our patented wireless UTC connectivity system and AutoGreen Technology.

Research and Development

Research and Development is an important part of our business.

We remain at the forefront of technology by continuously looking at ways to improve the functionality and reliability of our products.

Highway Agency specifications are just the starting point for us, as we aim to exceed the expectations of the customer in delivering systems which will allow their business to grow.

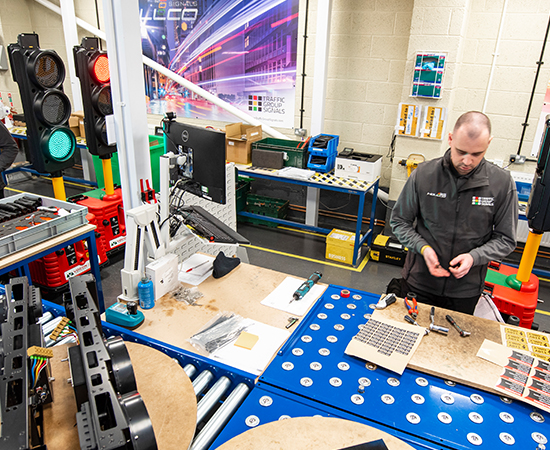

Manufacturing

Our UK based manufacturing capabilities are second to none, with a significant investment in lean manufacturing processes to ensure quality and efficiency.

This helps us meet the demand of customers whilst providing our production teams with a safe and comfortable working environment, enabling them to perform their best.

We’re now inviting customers to experience our factories, for more information click here.

Testing

Public and operator safety is paramount in the development of our products.

As such, all of our products and technologies undergo extensive factory and roadside acceptance testing before they are allowed to leave the factory.

Our sophisticated testing procedures and experienced technical department are well equipped to identify and resolve any issues.

The future

Our mission is to deliver product solutions that make for safer, greener and more efficient roadworks environments.

We are working on a range of products and technologies that allow greater connectivity, reliability and performance.

To find out more or to share your ideas, please get in touch!